Seems like common sense.

Seems like common sense.When workers are required to use gloves or boots or hardhats in order to do their jobs safely, the employer should pay for that equipment. Seemed like common sense to OSHA, as well, eight years ago when it began the process of issuing a standard codifying OSHA's previous practice of requiring employers to pay for workers' personal protective equipment.

Common sense, that is, to everyone except George Bush's OSHA which seems to be filled with very studious types who never have their fill of studying "complicated" issues. Never.

David James, a spokesman for the Labor Department, said, "The case has not fully been reviewed by the department and it deals with complicated issues that will affect different employers and employees in a variety of ways."Those would be public comments from the last century.

James said the department is reviewing public comments about the proposal before offering a final rule.

America's workers, however, are fed up with what the AFL-CIO and the United Food and Commercial Workers union call an "egregious example of unreasonable delay"

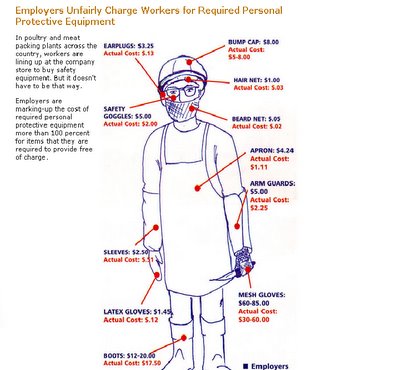

The labor organizations filed a lawsuit today in the US Court of Appeals in Washington DC to force OSHA to issue its "Payment for Personal Protective Equipment Standard" within 60 days. The standard, initiated in 1997, would require employers to pay the costs of protective clothing, lifeines, respirators, face shields, gloves, boots, hardhats and other equipment used by an estimated 20 million workers to protect them from job hazards.

The failure of the Bush administration to issue the standard has been devastating:

The lawsuit asserts that the Bush Administration's failure to act is putting workers in danger. By OSHA's own estimates, 400,000 workers have been injured and 50 have died due to the absence of this rule. The labor groups say that workers in some of Americas most dangerous industries, such as meatpacking, poultry and construction, and low-wage and immigrant workers who suffer high injury rates, are vulnerable to being forced by their employers to pay for their own safety gear because of OSHA's failure to finish the PPE rule.OSHA began work on the standard eight years ago in response to a court decision that said that OSHA's previous policy of requiring employers to pay for PPE was not legal because it was not specifically stated in OSHA's PPE standard. Many OSHA standards (such as lead, benzene, noise, respiratory protection, bloodborne pathogens, confined spaces, asbestos, and laboratory safety) already require emloyers to provide and pay for PPE, but where PPE is not required by a standard, OSHA's policy since its creation has been to require employers to pay for the PPE.

The tragedy of this situation is that this should have been a relatively short and simple standard to issue. OSHA issued a proposal in 1999, held four days of hearings which generated widespread support from safety professionals and unions, and almost no opposition from the business community. OSHA had originally planned to issue the standard in 2000, but missed that deadline. The Bush administration has set numerous deadlines since then and missed them all. In 2003, the AFL-CIO, UFCW and numerous other unions petitioned the agency for a standard.

According to the lawsuit, OSHA's failure to require employers to pay for PPE falls most heavily on immigrant workers:

In some jobs, including many low-wage jobs dominated by immigrant workers, PPE is a worker’s principal protection from harm. Poultry workers wear protective gear such as wire mesh gloves to protect their bodies from cuts and rubber boots to prevent them from slipping on wet floors. Welders wear face shields, welding aprons and gloves to protect them from hazards of the welding arc. Construction workers wear hard hats and steel-toed shoes to prevent injury from heavy objects falling on them. They rely on lifelines or lanyards to prevent falls from roofs and other high places. Other workers wear gloves, goggles, face shields, protective clothes and shoes, and other PPE.Despite its importance, personal protective equipment is the least effective means of protecting workers, behind eliminating the hazard or using engineering controls (such as ventilation) to separate the hazard from the worker. But the lawsuit notes that OSHA itself had expressed concern that the current situation

could also lead to perverse incentives for employers. Given a choice between engineering controls that the employer must pay for, and PPE that would be paid for by employees, employers would have a strong incentive to use PPE even though engineering controls would be more protective and might even be cheaper.The lawsuit also points out that the failure to require employers to pay for PPE has created an "inconsistent and confusing enforcement landscape."

Workers covered by many specific OSHA standards like asbestos and benzene receive PPE to protect them from these hazards at no cost, but workers who are exposed to hazards that are not covered by a specific rule can be required to pay for their own PPE. Thus, workers on the production line in a battery plant who are exposed to lead are provided protective clothing that is paid for by the employer, 29 CFR § 1910.1025(g)(1). But workers in the same facility on the charging line, who are filling batteries with sulfuric acid, can be required to pay for their own protective clothing, because sulfuric acid exposures are covered by the general PPE rule.The lawsuit argues that the court should force OSHA to issue the standard because the Administrative Procedure Act (APA), which governs the development of regulations

directs agencies to conclude matters presented to them “within a reasonable time,” and authorizes courts to “compel agency action . . . unreasonably delayed.” OSHA’s failure to complete the PPE rule almost eight years after it was first proposed represents an egregious instance of unreasonable delay. This is an uncomplicated rulemaking on a straightforward, but significant, issue of importance to worker safety and health. This Court should direct OSHA to complete the PPE rule within 60 days after the Court’s order.The lawsuit called OSHA's failure to act an "egregious example of unreasonable delay."

"Nothing is standing in the way of OSHA issuing a final PPE rule to protect worker safety and health except the will to do so. It is long overdue that the agency take action on protective equipment. Now, we are asking the courts to force OSHA to act," said Joseph Hansen, UFCW International President.Related Documents

“The Bush Administration’s failure to implement even this most basic safety rule spotlights how it has turned its back on workers in this country,” said AFL-CIO President John Sweeney. “Too many workers have already been hurt or killed. The Bush Department of Labor should stop looking out for corporate interests at the expense of workers’ safety and health on the job.”

Text of the Lawsuit

Press Release in English

Press release in Spanish